Part 2: How Do Force Sensing Linear Pots Work?

Like any potentiometer, Force Sensing Linear Pots have 3 leads. There's a Wiper terminal and two end terminals, which we'll label T1 and T2.

Here's a pic of the sensor we're using:

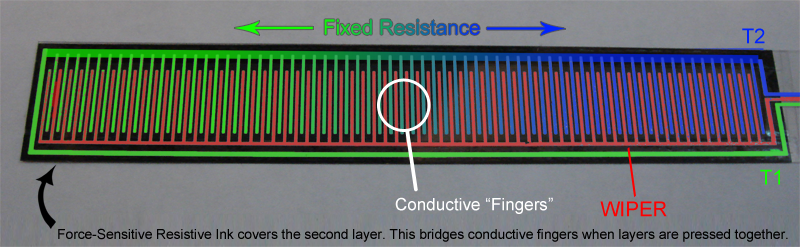

You may have a sensor with different print layout, but the concepts should be the same. Here's that same sensor with the parts labeled:

Measuring position works exactly like a standard rotary-knob potentiometer. Between the T1 & T2 traces is a long fixed resistor spanning the entire length of the sensor area, 10k in our case. When force is applied, the wiper makes contact at some point along this resistive span. For position, we need to find either RT1-WIPER or RT2-WIPER, so we'll apply Vcc at T1, ground T2, and read voltage at the wiper.

Traditional potentiometers don't measure force, so here's where things differ. A twist-pot has (virtually) zero wiper resistance; the wiper directly contacts some point on the fixed resistance. But on our FSLP, the fingers on the wiper and fixed resistance are partially bridged by resistive ink on the 2nd layer. The resistance of this connection decreases as the layers are pressed together.

Thus, the FSLP Wiper has an effective resistance value that's inversely proportional to force. So to read force, we'll measure RWIPER.

Now that we know how it works, let's breadboard it...